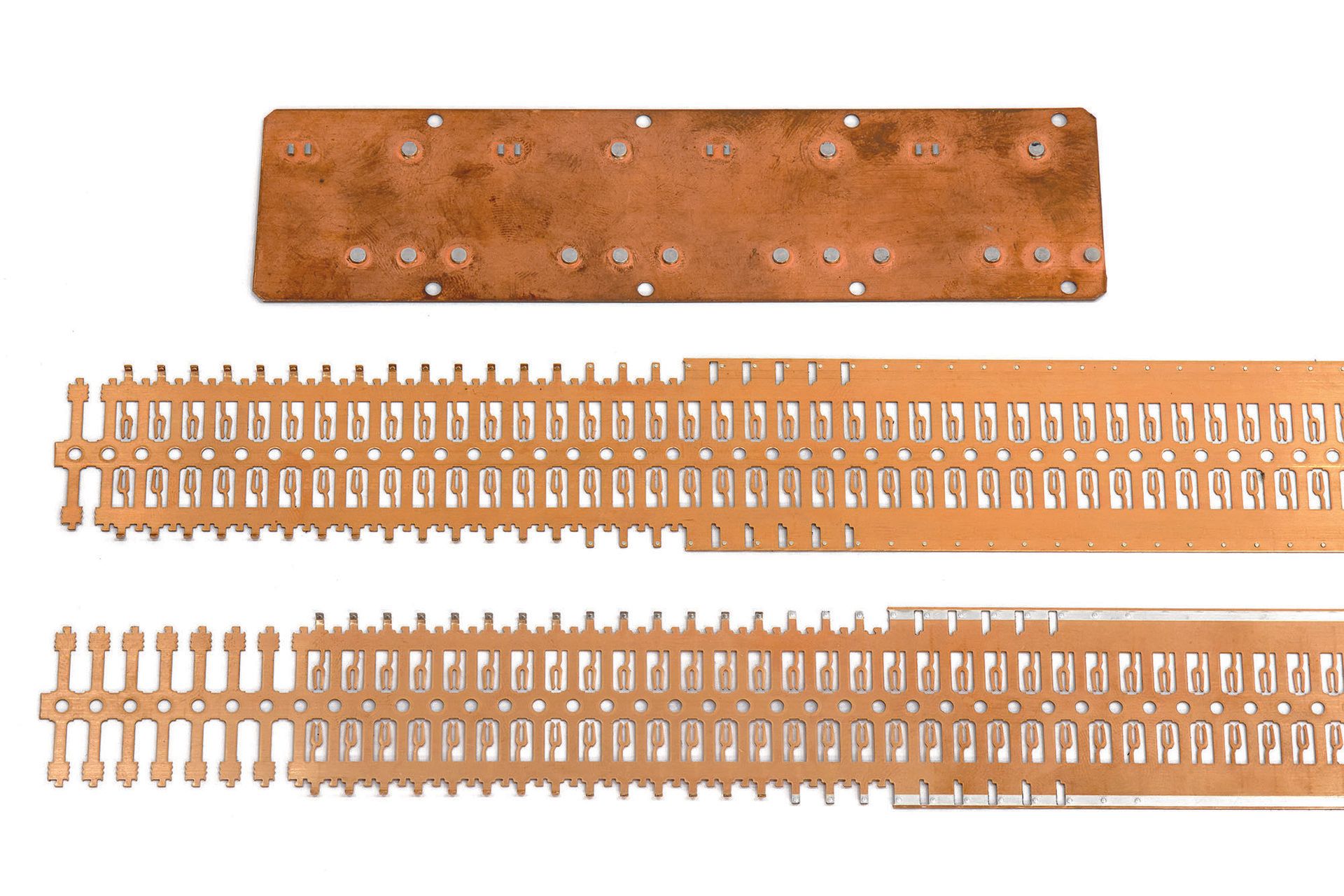

S. Bernhard GmbH concentrates all the expertise of the WACHSMUTH GROUP in punching and bending technology. It has the latest automatic punching presses which, among other things, enable highly complex progressive tools and the production of the most complex punched parts in large quantities.

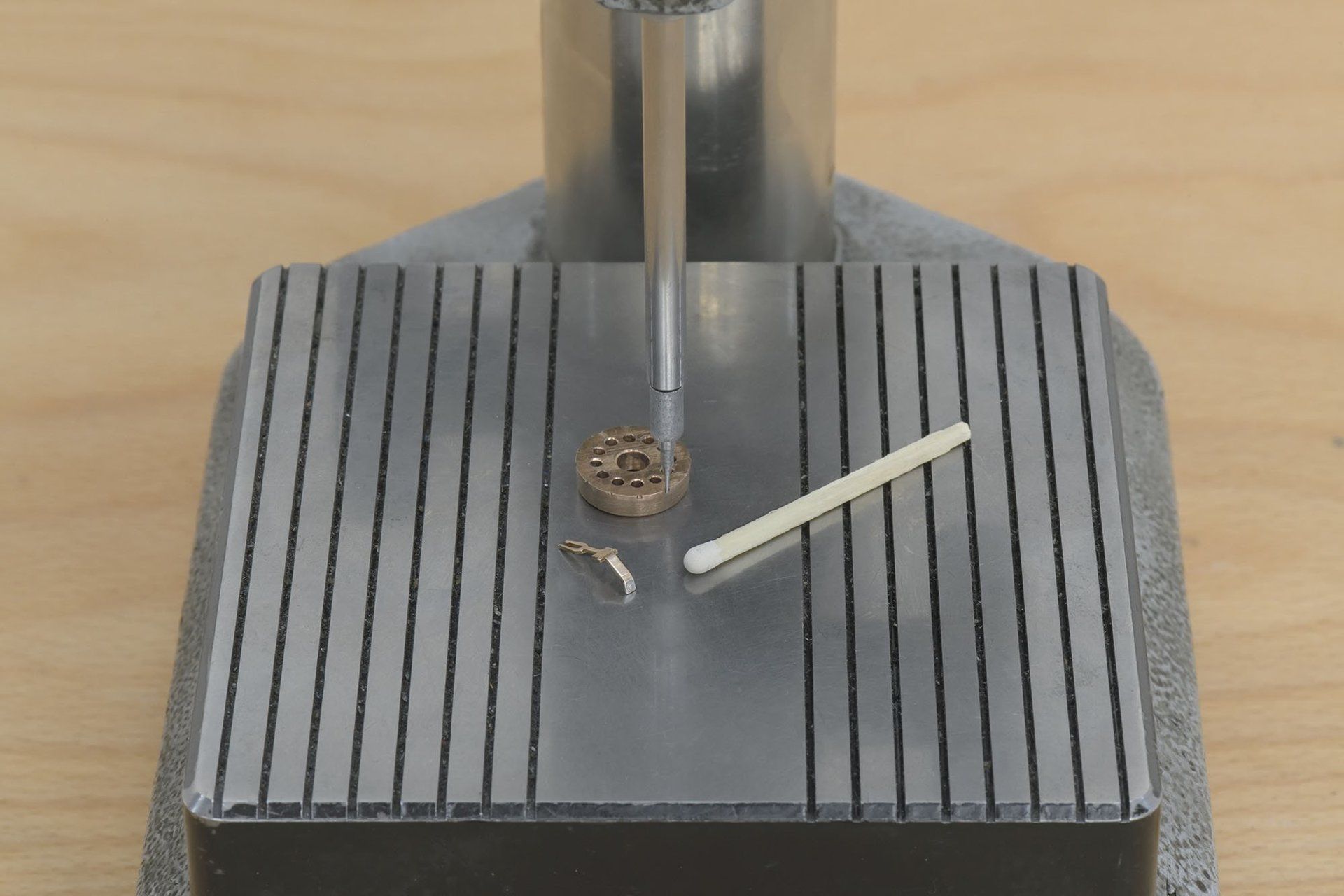

Strict quality control and extensive technical knowledge of billions of stamped parts that have already been produced enables the fulfillment of all standards and specifications, including the highest quality requirements for safety-relevant parts (that require documentation) in the automobile industry.

Particular attention is placed on complicated parts and parts that are extremely difficult to produce, such as deep-drawing and precision forming expanded metals or producing welded contacts. But simpler standard products also benefit from our extensive experience.

Production of

- stamped parts that require / do not require documentation for automotive applications

- more than 3,000,000,000 parts per year

Services at a glance

- unched and formed parts for all applications in many material thicknesses

- Automotive special products

- Thermoformed parts according to sample or drawing

- Welded contacts

- Wick holder for tea lights

Technical equipment

- Automatic punching presses from Linde, Moll and Bruderer

- Bihler punching / bending machines with welding technology

- Pressing forces of 50 t – 350 t

- eccentric presses up to 240 t.

- Processing of material thicknesses

of 0.1 mm to 5 mm iron and non-ferrous metals - IATF 16949 certified

- More than 50 employees

S. Bernhard GmbH

Stanz- und Drahtbiegetechnik

Gielster Stück 1

· 58513 Lüdenscheid

· Germany

Fon: +49 2351 673030